Cement and concrete are two materials that are often used interchangeably, but they are not the same thing. Cement is just one component of concrete, and it plays a critical role in its composition. This article aims to explain the difference between cement and concrete.

Cement is a fine powder made of limestone, clay, and other minerals. It is a binding material that hardens when water is added to it. It is a crucial component in the construction industry since it is used to bind different materials together, to fill joints and gaps, and to create different architectural and decorative features.

Concrete, on the other hand, is a mixture of cement, water, sand, gravel, and other additives that are combined in specific proportions to create a strong and durable building material. Concrete is used for building structures like buildings, bridges, highways, sidewalks, and even small home projects like patios and driveways.

The fundamental difference between cement and concrete lies in their composition. Although cement is a crucial component of concrete, it makes up only a small portion of it. On the other hand, concrete is a combination of cement, aggregates, and water, which makes up the bulk of its composition.

Cement is produced by crushing and grinding limestone, shale, and clay into a fine powder. The powder is then mixed with other minerals like gypsum, which slows down the hardening process, and fly ash, which provides better workability. The result is a finely ground powder that hardens when mixed with water.

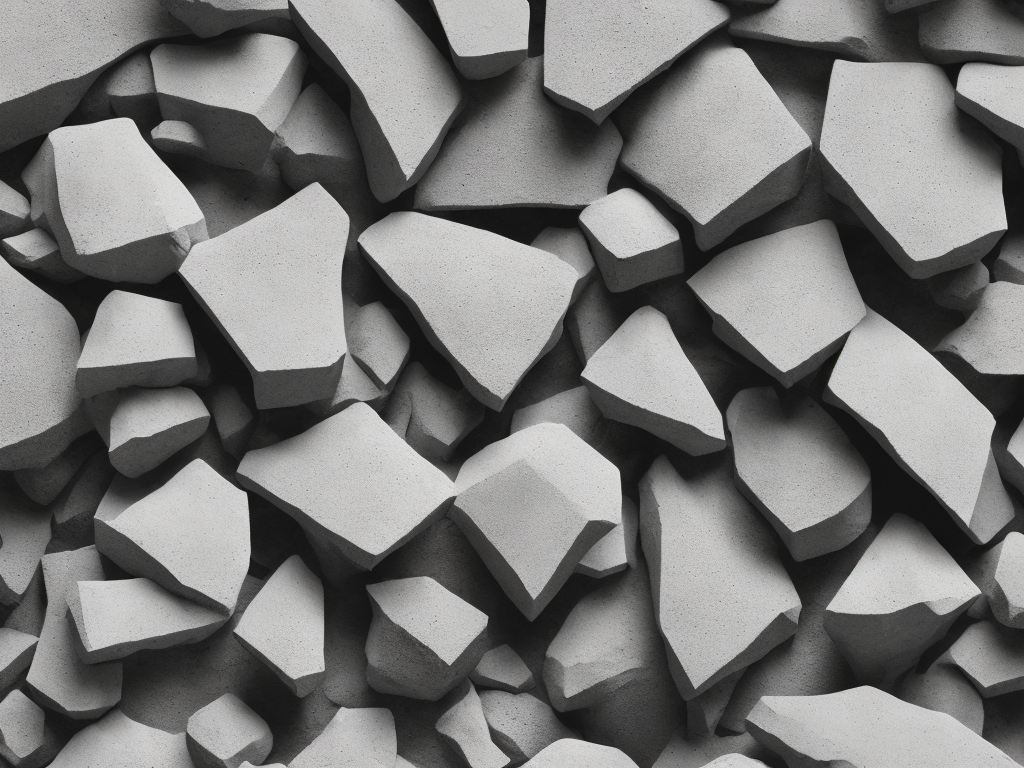

On the other hand, concrete is made by mixing cement with water, aggregates, and other additives. Aggregates can be made up of sand, gravel, crushed stone, or recycled concrete. These materials are mixed in specific proportions to create a strong and durable material that can withstand the weight of structures and resist erosion and weathering.

While cement hardens when mixed with water, it is not strong enough on its own to build structures. Cement paste is brittle when dry, and it cracks easily. However, when mixed with aggregates, cement paste creates a composite material that is strong and durable.

Another difference between cement and concrete is their application. Cement is used primarily in construction projects as a bonding agent and filling material. On the other hand, concrete is used in a range of applications, from structures like buildings and bridges to roadways and even decorative features like countertops and statues.

Cement and concrete also differ in terms of their strength. The strength of concrete is determined by the proportion of its components and the quality of the materials used. Generally, the higher the proportion of cement in concrete, the stronger it is. Other factors that contribute to the strength of concrete include the size and shape of the aggregates, the amount of water used in the mix, and the curing time.

Cement is a major carbon emitter, and its production accounts for around 8% of global carbon emissions. The problem lies in the production process, which requires a significant amount of energy and emits a large amount of CO2 into the atmosphere. To minimize this impact, manufacturers are exploring different ways to reduce carbon emissions, such as using alternative fuels like biomass and waste materials, reducing the amount of clinker, and increasing the use of supplementary cementitious materials like fly ash and slag.

In conclusion, cement and concrete are two different materials that are often used interchangeably. Cement is a fine powder that hardens when mixed with water, and it is a crucial component in the construction industry. On the other hand, concrete is a composite material made up of cement, water, aggregates, and other additives, and it is used for building structures like buildings, bridges, and roadways. The difference between cement and concrete lies in their composition, application, and strength. Cement makes up only a portion of concrete, and concrete is stronger than cement paste alone. Cement production is a significant contributor to global carbon emissions, and manufacturers are exploring ways to minimize its impact.

Self-Instruct

Self-Instruct