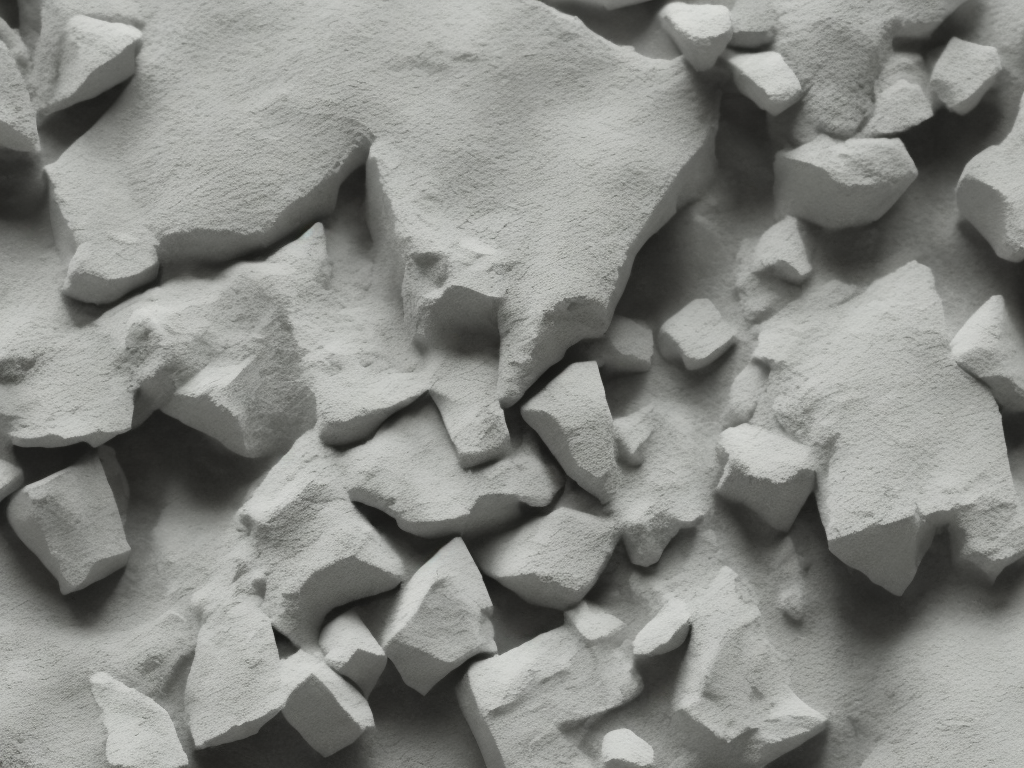

Cement is the binding agent that is used in the construction industry. It is a grey powder that is made by mixing materials like limestone, clay, and minerals which are then heated at high temperatures. Cement plays a vital role in the construction industry, and there are various types of cement available in the market. Two popular types of cement are Ordinary Portland Cement (OPC) and Portland Pozzolana Cement (PPC). This article will discuss the difference between OPC and PPC cement.

OPC Cement

Ordinary Portland Cement (OPC) is the most common cement used in the construction industry. It is made by heating a mixture of limestone and clay at high temperatures. The resulting product is a fine powder that is grey in color. OPC has different grades like OPC 33, OPC 43, and OPC 53.

OPC 33: This type of cement is used for plastering works, non-structural works, and low-grade concrete works.

OPC 43: This type of cement is commonly used in general civil engineering works, like the construction of buildings, roads, bridges, and pavements.

OPC 53: This type of cement is used in high-grade concrete works, like those required in the construction of dams, large buildings, and heavy structures.

PPC Cement

Portland Pozzolana Cement (PPC) is a type of cement that is made by mixing Portland cement clinker with pozzolanic materials like fly ash, volcanic ash, and silica fumes. The use of pozzolanic materials improves the strength and durability of cement. PPC also has different grades like OPC, such as PPC 33, PPC 43, and PPC 53.

PPC 33: This type of cement is commonly used in masonry works, plastering works, and decorative concrete finishes.

PPC 43: This type of cement is used in general construction works like the construction of buildings, roads, bridges, and pavements.

PPC 53: This type of cement is used in high-grade concrete works like those required in the construction of dams, large buildings, and heavy structures.

Difference between OPC and PPC Cement

OPC and PPC cement have some significant differences, and they are listed below:

1. Raw Materials Used

OPC cement is made from a mixture of limestone and clay, while PPC cement is made by mixing Portland cement clinker with pozzolanic materials like fly ash, volcanic ash, and silica fumes.

2. Setting Time

OPC cement has a faster setting time, which means it sets quickly. PPC cement has a slower setting time, which gives time for the concrete to be placed and leveled.

3. Compressive Strength

OPC cement has higher compressive strength compared to PPC cement. OPC cement has a compressive strength of 33 MPa, 43 MPa, and 53 MPa, while PPC cement has a compressive strength of 33 MPa, 43 MPa, and 53 MPa.

4. Durability

PPC cement is more durable compared to OPC cement because it uses pozzolanic materials that enhance the strength and durability of the cement.

5. Heat of Hydration

OPC cement has a higher heat of hydration compared to PPC cement, which means it releases more heat during the setting process. This can sometimes lead to cracks in the concrete.

6. Cost

PPC cement is cheaper than OPC cement, which makes it more affordable for construction projects.

Which Cement to Choose – OPC or PPC?

When selecting the type of cement to use in construction, several factors need to be considered, like the type of project, the location, and the budget. Generally, if the project requires high strength concrete, OPC cement should be used. On the other hand, if the project doesn't require high strength concrete, PPC cement can be used, which can also be more cost-effective.

However, it is important to note that both OPC and PPC cement have their advantages and disadvantages. OPC cement has a faster setting time and higher compressive strength, but it is more costly. PPC cement is more affordable, durable, and has a slower setting time.

Conclusion

In conclusion, the choice of cement depends on the type of construction project, location, and budget. OPC cement has been the traditional choice for years, but PPC cement has gained popularity in recent years due to its affordability and durability. When choosing cement, the compressive strength, durability, setting time, and cost should be considered to ensure that all project requirements are met.

Self-Instruct

Self-Instruct