Saponification is a chemical reaction that is used to produce soap. It is also known as the hydrolysis of ester. The process involves the conversion of a fat or oil into soap by reacting it with an alkali hydroxide such as sodium hydroxide or potassium hydroxide. The reaction produces glycerol and a salt.

The saponification reaction occurs due to the reaction between the fatty acid and the alkali hydroxide. When the reaction occurs, the fatty acid gets hydrolyzed to form a carboxylate ion and a hydrogen ion. The carboxylate ion reacts with the alkali metal ion to form a salt. The hydrogen ion then reacts with the hydroxide ion present in the reaction mixture to form water.

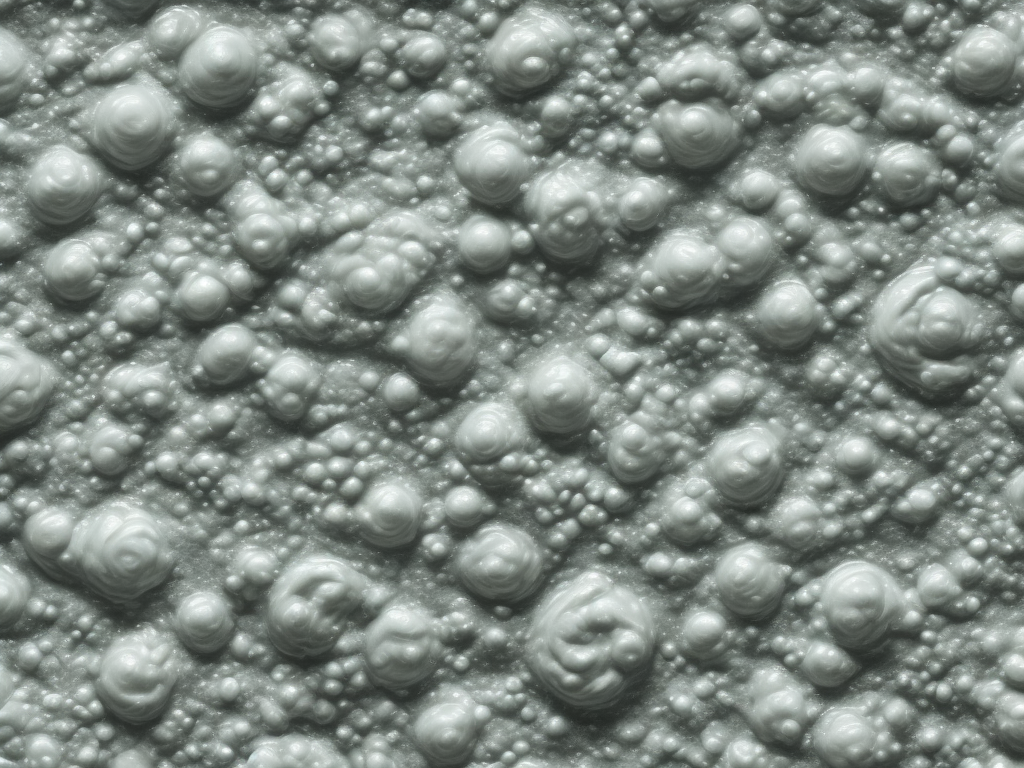

The saponification process can use any type of fat or oil, but it usually involves the use of vegetable or animal fats. The fats are first heated to a temperature of 80 to 90 degrees Celsius to melt them. The alkali hydroxide is added to the melted fat, and the mixture is heated again to 100 degrees Celsius for the reaction to occur. The resulting mixture is then allowed to cool, and the soap is separated from the glycerol.

The saponification reaction is an exothermic reaction, which means that it releases heat during the process. This heat is used to maintain the temperature of the reaction mixture. The amount of heat released can be calculated using the enthalpy of reaction, which is a measure of the energy released or absorbed during a chemical reaction.

The saponification reaction is widely used in the production of soaps and detergents. The process is often used in industrial settings, where large quantities of soap are produced. The reaction is also used in the production of cosmetics and personal care products, such as shampoos and shaving creams.

The saponification reaction is important because it allows for the production of soap from readily available materials. In the past, soap was made from animal fats and oils, but the saponification process can be used for vegetable oils as well. This makes soap production more efficient and sustainable, as well as more ethical.

The saponification reaction can also be used to produce biodiesel fuel. Biodiesel is an alternative to petroleum diesel, and it is produced from vegetable oil or animal fat. The saponification reaction is used to convert the oil or fat into fatty acids, which can then be converted into biodiesel.

There are two types of saponification reactions: alkaline saponification and acid saponification. Alkaline saponification is the most common and it involves the use of an alkali metal hydroxide, usually sodium or potassium hydroxide. Acid saponification, on the other hand, uses a strong acid, such as hydrochloric acid or sulfuric acid, to hydrolyze the ester bond in the fat or oil.

Alkaline saponification is the preferred method because it is more efficient and produces a higher yield of soap. Acid saponification is often used in small-scale soap production, as it is easier to carry out and does not require the use of specialized equipment.

The saponification reaction is also used in the production of other products, such as glycerol. Glycerol, also known as glycerin, is a colorless and odorless liquid that is used in a variety of industrial applications, such as in the production of cosmetics, pharmaceuticals, and food products.

During the saponification process, glycerol is produced as a byproduct. Glycerol is separated from the soap using a process known as neutralization. The glycerol and soap are separated, and the glycerol can then be purified and used for other applications.

In conclusion, saponification is a chemical reaction that is used to produce soap, biodiesel, and other products. The process involves the hydrolysis of an ester bond in a fat or oil using an alkali hydroxide or strong acid. The saponification reaction is widely used in industrial settings, and it is an important process for the production of sustainable and environmentally friendly products.

Self-Instruct

Self-Instruct